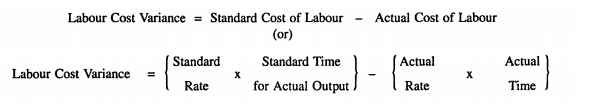

How would this unforeseen pay cutaffect United’s direct labor rate variance? Thedirect labor rate variance would likely be favorable, perhapstotaling close to $620,000,000, depending on how much of thesesavings management anticipated when the budget was firstestablished. A template to compute the standard cost variances related to direct material, direct labor, and variable manufacturing overhead is presented in Exhibit 8-11. Calculate the labor rate variance, labor time variance, and total labor variance. Each bottle has a standard labor cost of \(1.5\) hours at \(\$35.00\) per hour. In this case, the actual hours worked are \(0.05\) per box, the standard hours are \(0.10\) per box, and the standard rate per hour is \(\$8.00\).

3 Compute and Evaluate Labor Variances

The labor efficiency variance is also known as the direct labor efficiency variance, and may sometimes be called (though less accurately) the labor variance. Using the standard and actual data given for Lastlock and the direct materials variance template, compute the direct materials variances. Standard costs are established for all direct materials used in the manufacturing process. Direct materials include all materials that can be easily and economically traced to the production of a product.

- The standard variable manufacturing overhead rate per direct labor hour was established as $3.

- The same calculation is shown as follows using the outcomes of the direct labor rate and time variances.

- This determination may stem from meticulous time and motion studies or negotiations with the employees’ union.

- The standard number of hours represents the best estimate of a company’s industrial engineers regarding the optimal speed at which the production staff can manufacture goods.

- This is a favorable outcome because the actual hours worked were less than the standard hours expected.

- How would this unforeseen pay cutaffect United’s direct labor rate variance?

Causes of direct labor efficiency variance

Total variable manufacturing overhead costs per the standard amounts allowed are calculated as the total standard quantity of 37,500 times the standard rate per hour of $3 equals $112,500. During the period, Brad projected he should pay $112,500 for variable manufacturing overhead to produce 150,000 units. As mentioned previously, standard rates and quantities are established for variable manufacturing overhead.

7 Direct Labor Variances

Total direct labor costs per the standard amounts allowed are calculated as total standard quantity (37,500) times standard rate per hour ($18) equals $675,000. During the period, Brad projected he should pay $675,000 for direct labor to produce 150,000 units. The variable manufacturing overhead variances for NoTuggins are presented in Exhibit 8-10. Refer to the total variable manufacturing overhead variance in the top section of the template. Total standard quantity is calculated as standard quantity of the cost driver per unit times actual production, or 0.25 direct labor hours per unit times 150,000 units produced equals 37,500 direct labor hours. The standard variable manufacturing overhead rate per direct labor hour was established as $3.

When discussing direct labor, price is referred to as rate, and quantity is referred to as efficiency. Variances between the standard and actual amounts are what are the branches of accounting how they work caused by a difference in efficiency or rate. The total direct labor variance is separated into the direct labor efficiency and direct labor rate variances.

Its core function lies in quantifying this difference, providing insight into whether a business optimally leverages its labor force. A positive variance signals higher efficiency, contrasting a negative variance that suggests lower productivity than projected. As demonstrated in this chapter, standard costs and variance analysis are tools used to project manufacturing product costs and evaluate production performance. Standard costs variance analysis is used to determine the variances between the standard amounts projected for manufacturing costs and the actual amounts incurred. Any variance between the standard amounts allowed and actual amounts incurred should be investigated.

Review this figure carefully before moving on to thenext section where these calculations are explained in detail. The completed top section of the template contains all the numbers needed to compute the direct labor efficiency (quantity) and direct labor rate (price) variances. The direct labor efficiency and rate variances are used to determine if the overall direct labor variance is an efficiency issue, rate issue, or both. Connie’s Candy paid $1.50 per hour more for labor than expected and used 0.10 hours more than expected to make one box of candy.

Typically, the hours of labor employed are more likely to be under management’s control than the rates that are paid. For this reason, labor efficiency variances are generally watched more closely than labor rate variances. Direct Labor Efficiency Variance is the measure of difference between the standard cost of actual number of direct labor hours utilized during a period and the standard hours of direct labor for the level of output achieved. For example, the number of labor hours taken to manufacture a certain amount of product may differ significantly from the standard or budgeted number of hours.

For Jerry’s Ice Cream, the standard allows for 0.10labor hours per unit of production. Thus the 21,000 standard hours(SH) is 0.10 hours per unit × 210,000 units produced. This variance should be investigated to determine if the savings will be ongoing or temporary. Due to the higher than planned hourly rate, the organization paid $22,500 more for direct labor than they planned. This variance should be investigated to determine if the actual wages paid for direct labor can be lowered in future periods or if the standard direct labor rate per hour needs to be adjusted.

Direct material and direct labor are considered variable manufacturing costs, since the total amount for these costs changes based on production. Manufacturing overhead is typically a mixed cost consisting of a variable and a fixed component. Fixed manufacturing overhead is, by definition, fixed and should not change as long as production remains within the relevant range. The total amount of variable manufacturing overhead changes based on production so it has a quantity and price standard. Since direct material, direct labor, and variable manufacturing overhead have quantity and price standards, they are analyzed using the standard costs variance analysis method presented in this chapter. To illustrate standard costs variance analysis for variable manufacturing overhead, refer to the data for NoTuggins in Exhibit 8-1 above.

An investigation may reveal that employees took longer than 0.25 hours to make each unit, which could mean additional training or another appropriate solution. Labor efficiency variance compares the actual direct labor and estimated direct labor for units produced during the period. Possible causes of an unfavorable efficiency variance include poorly trained workers, poor quality materials, faulty equipment, and poor supervision. Another important reason of an unfavorable labor efficiency variance may be insufficient demand for company’s products.